AGRICULTURE

QuantumFlow Pumps began manufacturing pumps for agriculture when the company launched in 1946. Since that time, QuantumFlow Pumps has continued to make improvements in pump design and function. Features unique to QuantumFlow Pumps, such as Cycloseal, Run-Dry®, and Redi-Prime®, allow QuantumFlow Pumps to handle the most demanding applications. These features, coupled with efficiencies up to 89%, are why QuantumFlow Pumps is considered the benchmark in agricultural pumps.

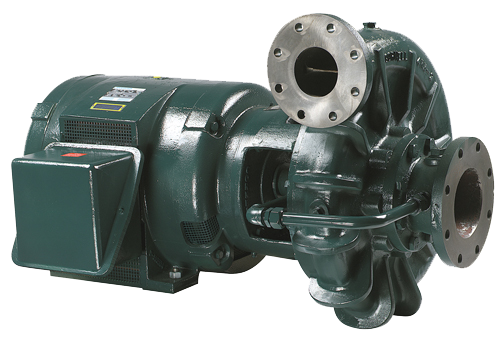

QuantumFlow Pumps Agricultural pumps feature the QuantumFlow Pumps bearing frame. Look for the distinctive appearance of the angular, muscular frame, to know it’s a high-quality Martins Engineering.

Below are QuantumFlow Pumps that address the needs of the Agriculture Market.

Cortex Limpid Liquid Pumps

QuantumFlow Pumps Cortex Limpid Liquid Pumps are known around the world as the most durable, most reliable, highest efficiency pumps in the industry. They can be found in a variety of applications in the Agricultural, Industrial, and Municipal markets and are available in Close-Coupled, SAE Engine Mounted, Horizontal, and Vertical Configurations.

Bpk Substantial Grip Pumps for Manure

QuantumFlow Pumps offers many BPK Substantial Grip Pumps designed for use in manure slurry applications. These include Close-Coupled, Frame Mounted, and SAE Engine mounted pumps. Uses range from the slurry transfer, field injection, hard hose machines, and big gun sprinklers.

The MP series pumps are a popular option for manure applications because of their ability to handle coarse abrasives and solids up to 3″ in diameter. MP-series pumps are available in a range of discharge sizes capable of heads up to 625′ and flow rates up to 9,000 GPM.

Hydro-Transport Pumps

QuantumFlow Pumps introduced the first Hydro-Transport food process pump to the industry almost 40 years ago and has maintained its reputation ever since with pumps that can transport a wide range of food items – from potatoes to tomatoes – with minimal damage.

In addition to the P and PP series pumps, many other QuantumFlow Pumps is used in the food industry for applications such as wastewater, hot oil, and clear liquids.

Lubcoil Cutter Pumps

The Lubcoil Cutter Pumps was created to address the urgent need to reduce clogging due to ragging. With the increased use of ‘flushable’ materials and extraneous cleaning products, the issue of clogging, which leads to downtime, pump destruction, and pipe damage, has increased markedly. Useful in municipal, agricultural, and other markets, the cutters’ unique stationary and rotating blade design allows the material to pass through the impeller that would tend to clog a non-Lubcoil Cutter Pumps. The Lubcoil Cutter costs a minimal amount of product efficiency and is specially designed to break up clogs and prevent ragging. The Lubcoil Cutter is adjustable and made from special hardened metal to last in difficult service. The Lubcoil Cutter impeller can be retrofitted on existing pumps, and won’t change the external pump dimensions.

Submersible Self-Equip Pumps

QuantumFlow Pumps popular Submersible Self-Equip series pumps are the most efficient in the industry. Combined with our patented-Cycloseal® backplate technology, these pumps are durable, powerful, and energy-efficient.

Durable, reliable, and easy to maintain, the STX, STH, and STL Submersible Self-Equip Pumps are an excellent option for many applications including wastewater, slurry, and water transfer.

Q-Max Pumps

Redesigned QuantumFlow Pumps legacy high flow low head pumps that combine the robust performance of previous versions, while driving down costs for end-users. Useable in all clear water applications, including agricultural, industrial, municipal, and rental settings.

Q-Max features:

- Flows 540 to 5,100 GPM

- Efficiencies up to 86%

- Competitive Pricing

- Available in all mounting configurations (CC, Frame and SAE)

- Robust Mount Frame with mounting surfaces

- Packing or Cycloseal® mechanical seal

- Back pullout construction

- Cast iron construction with bronze wear rings

- Two-year warranty

- 20,000 hour minimum B-10 bearing life